Occasionally it is required when repairing clocks to work at height or access clock dials and bells that are awkward to get to. Sometimes scaffolding which can be quite expensive is required, however using roped access can be a safe and cost effective alternative.

In order to be able to use roped access a clockmaker is required to undergo and pass rigorous training with IRATA (Industrial Rope Access Trade Association). This certification lasts three years before it is required to be renewed.

Health and Safety regulations require that a second person is on site at all times that roped access is being undertaken. This is to ensure that should the situation arise, the emergency services can be called promptly without delay.

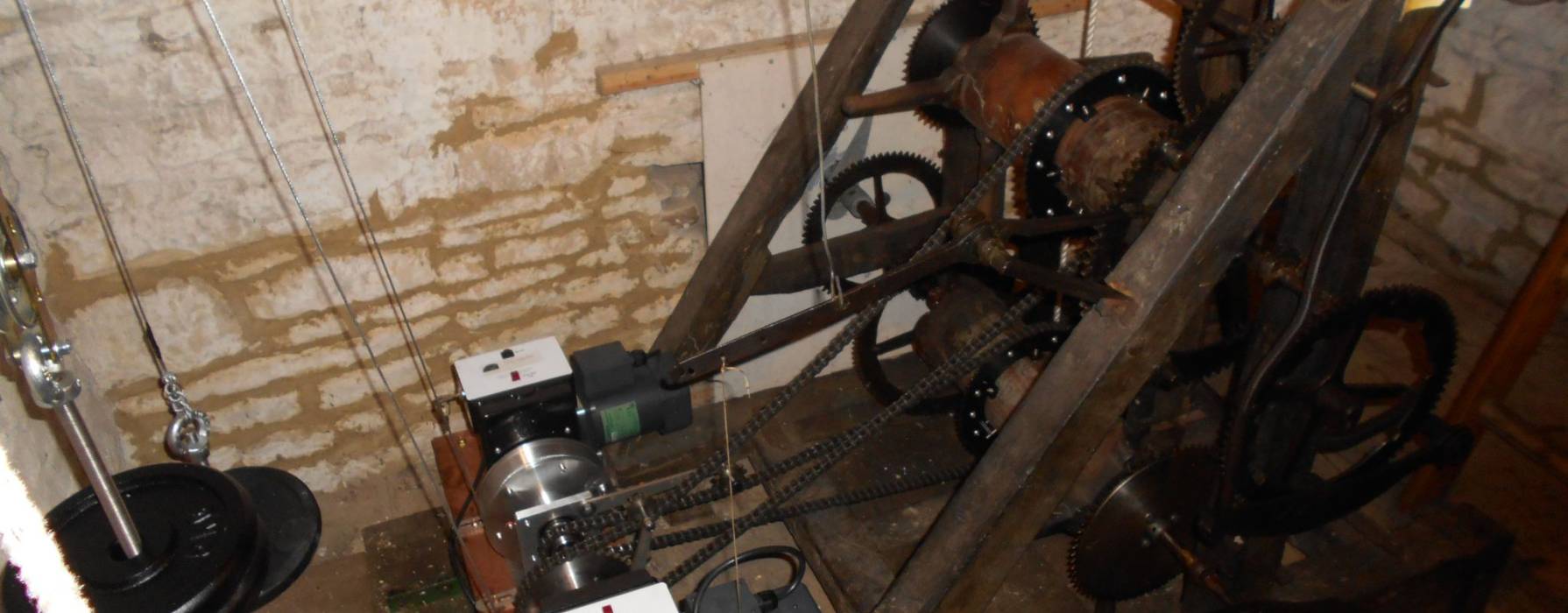

Roped Access safety methods can also be deployed in other situations such as a secondary safety backup system when using ladders. This is illustrated in the series of photographs below highlighting the servicing of a Church Bell and associated striking equipment. The equipment was situated on the top of a very steep Church roof. Although a ladder and roof ladder was used as the primary means of access, whilst a secondary backup safety system was employed using a safety harness and secured ropes. A catapult fired a line over the Church roof and this was used to pull a rope over the roof which was then securely tied. The clockmaker used the rope secured to his harness as a backup safety system while attending to the bell equipment from a roof ladder.

The safety of our clockmakers is paramount and this also gives peace of mind not only to ourselves but also to our customers.