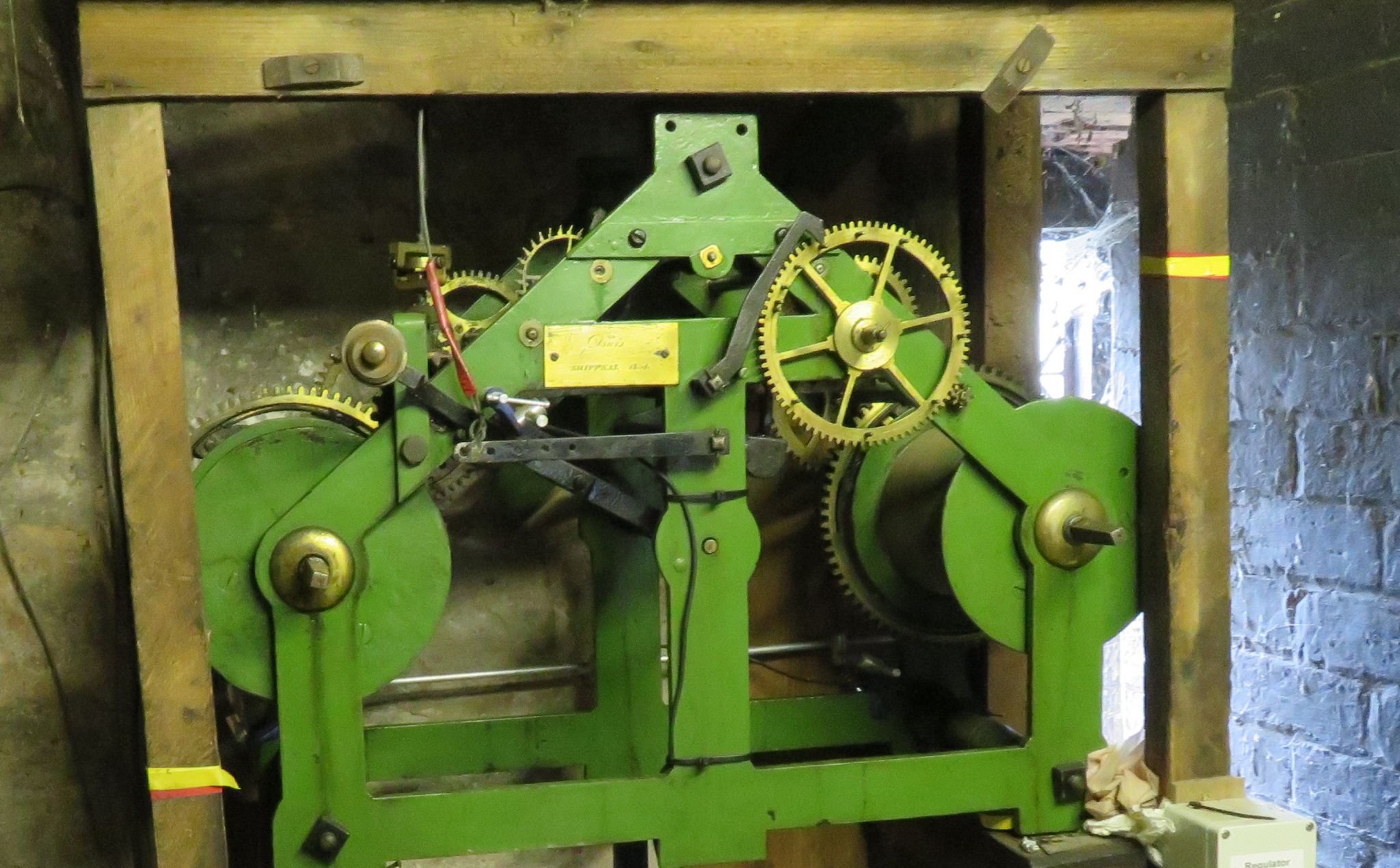

Clock Hammers – St Luke’s Church, Silverdale

During our Annual Service visit, on checking the hammer check springs which are set to keep the clock hammer heads just clear of the sound bow of the bell. It became apparent that the securing screws which fix the springs to the mounting timbers were loose. This was due to the timber starting to rot and not enough stable wood to hold the screws in position.

We were then asked to to replace the rotten timbers, to make sure the clock hammers are striking the bells correctly. The clock hammers were removed as was the rotten timber. New timber was then cut to suit the original timbers and fixed in position.

The hammers were then re-fitted and reconnected to the clock, the hammer pull offs were then checked to make sure the hammers were clear of the bells and no damage could be caused when change ringing.